Solutions for Common Challenges in the Industrial Sector

Industrial operations are becoming more complex. By turning machine and location data into actionable insights, you can optimize performance.

Discover how:

Prevent Downtime with Predictive Maintenance

- Schedule maintenance based on operating hours, error codes, and sensor data

- Receive early warnings and reduce emergency repairs

Take Control of Energy and Emissions

- Monitor fuel, AdBlue, CO₂, and NOx consumption

- Gain insights and generate reports for CSRD, ESG, and WPM compliance

Real-Time Monitoring of Fill Levels, pH, and Turbidity

- Manage tank routes, refill schedules, and threshold levels

- Use autonomy dashboards to ensure timely refilling or emptying

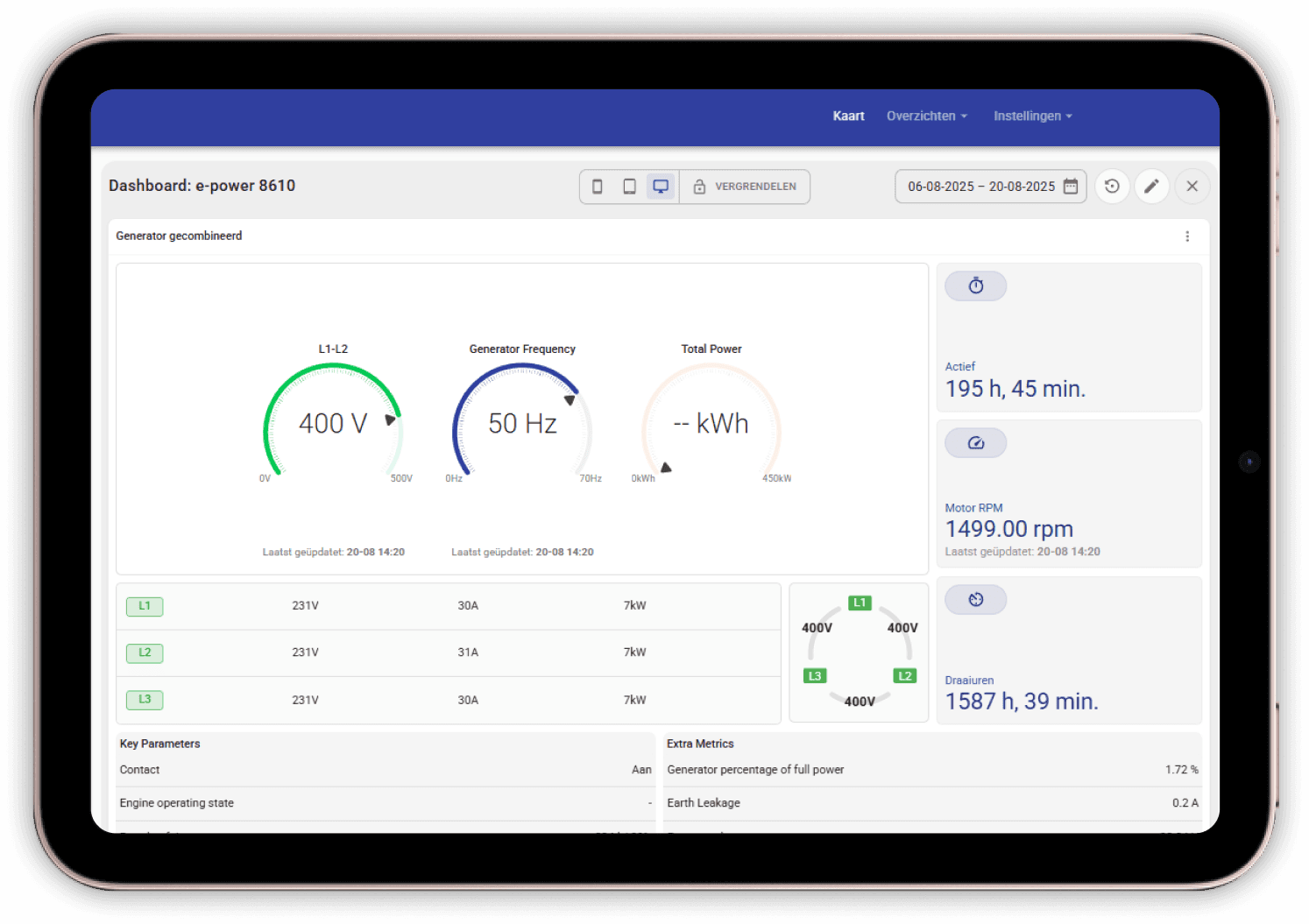

Real-Time Monitoring of Your Machines and Vehicles

- Improve service management through data-driven decisions

- Respond immediately to alerts and error messages from your assets

- Align processes by setting triggers based on threshold values

Maximize Machine Utilization and ProductivityMaximize Machine Utilization and Productivity

- Gain insights into usage time, location, and utilization per shift or period

- Detect downtime and improper use

Plan Smarter with Limited Staff

- Link machine data to operators

- Access team performance insights and improve scheduling

Automate Compliance and Audit Reporting

- Generate real-time reports for CSRD, WPM, ESG, and the Machinery Directive

- Reduce manual work and minimize human error

Protect Your Assets with Track & Trace

- Global monitoring with geofencing and motion detection

- Recover lost machines and equipment faster, reducing asset loss

- Even track handheld tools and monitor which technician or vehicle holds specific inventory

Regent Insight turns data into action - for a more efficient, safer, and sustainable operation. Contact one of our consultants or request a free demo today